Getting it UpThe inital plan was to build the towers one section at a time using a gin pole. Fortunately a local K0LW who is experienced in such things counciled me to consider building the tower on the ground and then lifting the tower up in one motion with a crane. As with such things, initially I had not done any actual work on the project and was not wanting to invest in expensive crane services - however the long summer had given me time to get a more educated view on just how much work building that tower one stick at a time would be. Over the summer I had the chance to attend the disassembly of some of the towers at Stan K5GO's site. He stripped about 25 big beams and laid down 8 towers all in one day using a crane; it was phenominal. At about the same time, I had found some 55G off a commercial tower and the act of first loading the 25 sections at 110 lb each onto the trailer, and then later unloading them out at my QTH was an education. The combination of seeing how efficient (and safe) a crane could and also feeling first-hand just how heavy those 55G sections are wiped away any reservation I had regarding making the investment in crane services. By the time all the antennas were up that year, a total of 4 cranes had been out to my QTH for work. I am a huge fan of using cranes in any big tower project. 160m Vertical - Rohn 25G

First to go up was the 160m full size vertical built from 25G. Guys were precut and attached to the tower with the plan of standing up the tower with the crane, sticking it to the base, and then tying off the guys from the bottom rank and moving upward. The lift point for this tower was about 90'. To my complete amazement the plan worked just fine - with the only concern being the amount of flex the top-most 40' of 25G showed when the crane lifted the tower up! Below is Eric KJ0D going up to remove the sling after the tower has been stood up and guys secured.

The base was made from a 25G section embedded in concrete and topped with an insulated base section that I was fortunate to get from K5GO. It's complete overkill for KW power levels but it looks fantastic!!!

At left is a completed guy anchor point for the 160m vertical.

Shown here are the fiberglass grips at the end of the rod. Heavy duty thimbles provide the transition to the EHS grip. A SS hose clamp is used on the live end of the grip to act as an ice shield. The last bit of excitement was to see if the 65,000 lb crane was going to become stuck in the mud at the 160m site. As the crane backed in his forward movement had stalled due to spinning tires. Fortunately when it came time to move the crane again, it was able to drive out without issue. 20m & 40m Towers - 55G Shown below is the 40m tower assembled and with the rotor mounted, waiting guy attachment and the beacon plate/thrust bearing.

Next to go up was the 40m tower. In the photo below the crane is setting up. The tower with attached fiberglass guys is visible on the right side.

Antennas for a fixed direction are monted at several points along the length of both the 40m and 20m towers. The mounting brackets used are of a K5GO design (shown right). Big angle stock connects to the tower with U-bolts and a fixed mast extends from the end.

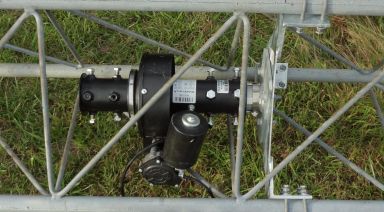

Alpha SPID Big Rak rotors are used on the 20m and 40m towers.

The 40m tower has a 3" DOM 1/4" wall mast. Shown at left is the custom-made adapter built by Grant KZ1W.

The 20m tower has a prototype KF7P shock reduction device which sets between the Alphaspid Big Rak rotor and the mast. The rubber in the gadget absorbs sharp forces that the antenna's rotational mass may hit the rotor with as well as providing some flexiblity along the z-axis of the rotor/mast assembly eliminating the need to get the alignment exact.

20m tower raised, guys attached and KJ0D on the way up to disconnect the lift sling. At the end of the day the 3 towers were standing tall. A dream come true.  |